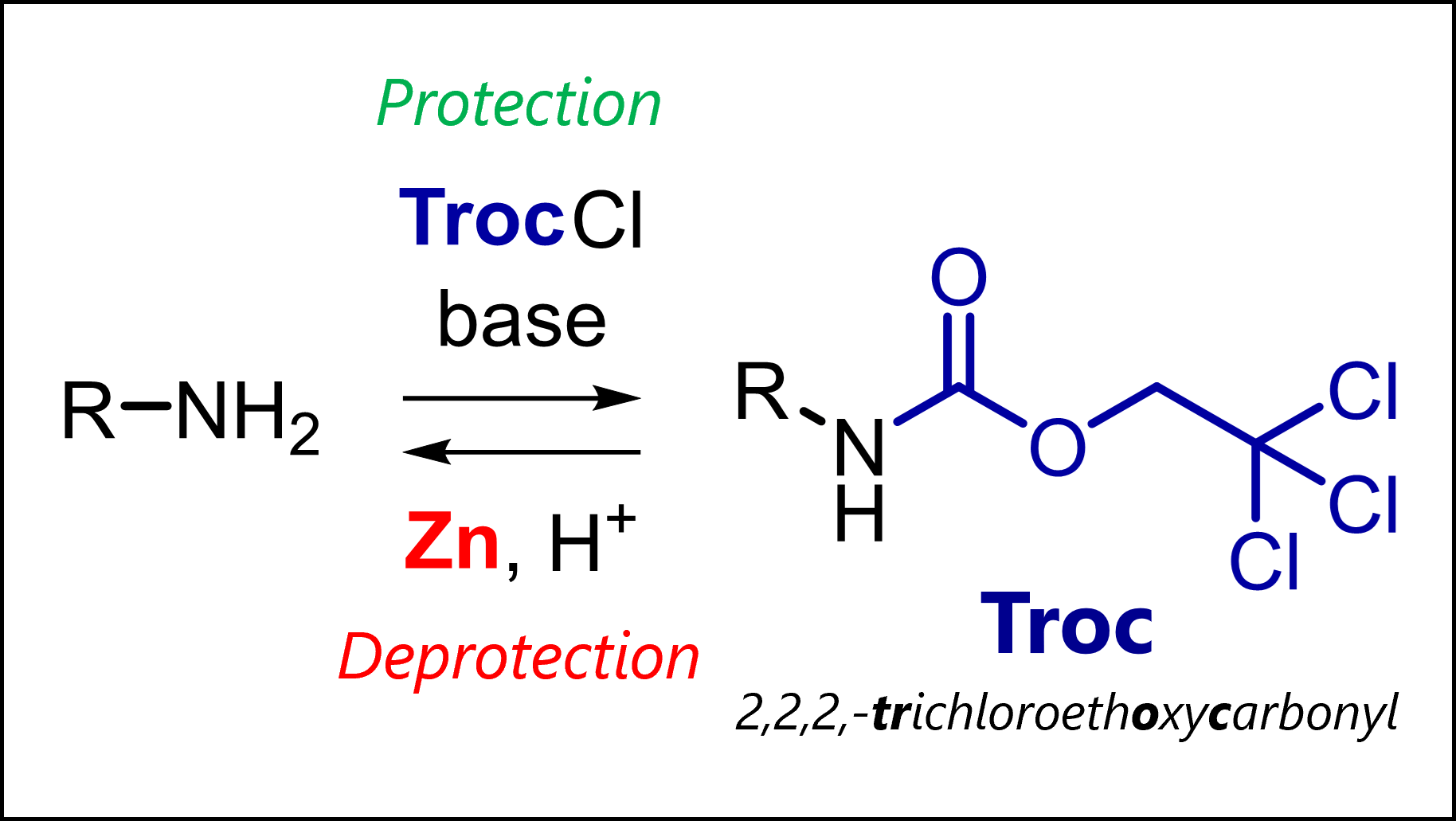

The Troc protecting group protects amines in organic synthesis. Troc is introduced with TrocCl and deprotected by reduction (Zn).

🫡 Hello! Here’s what you’ll learn here:

👀 Left: 3D model of Troc (chlorines in green!)

What is the Troc Protecting Group?

Troc (2,2,2-trichloroethoxycarbonyl) can convert amines or alcohols into stable carbamate or carbonate derivatives. This leads to a similar effect that we see in groups like Fmoc or Boc: the previously nucleophilic amine or alcohols loses its reactivity (driven by delocalization of electrons into the carbonyl system).

The nice thing is that Troc is orthogonal as the deprotection conditions for Fmoc (base), Boc (acid) or silyl groups like TBS (fluoride) do not remove it. Instead, it has a unique mechanism of reductive beta-elimination to release the free group.

Did you know: The Troc group was introduced by the legendary Robert Burns Woodward in the 1960s? (see below)

Troc Protection Mechanism

The Troc protecting group is introduced by reacting the free amine or alcohol with 2,2,2-trichloroethyl chloroformate (Troc-Cl) with addition of a base.

Most common protection conditions are Troc-Cl with pyridine in CH2Cl2 or THF. If the starting material is very polar, Troc-Cl with NaOH or NaHCO3 in water.

Troc Deprotection Mechanism

The Troc protecting group can be removed with certain reductive methods which all function via beta-elimination. Most common is use of zinc or other single-electron reductants that reduce the terminal carbon. The beta-elimination gives a free carbamate – an intermediate seen in mechanisms of many other protecting groups – that rapidly decarboxylates to the deprotected amine (or alcohol).

Most common deprotection conditions are Zn powder in THF/H2O or so-called couples/alloys consisting of mixtures of Zn-Pb or Cd-Pb. More rarely used, reduction with electrolysis also removes the Troc group.

Always remember protecting group stability or lability are always general (e.g., here: removal by reduction). Nothing in chemistry (or life) is black and white 🙂

Here is a neutral method (not reductive) using trimethyltin hydroxide. [1]

A fascinating point is that under the right conditions, Me3SnOH actually deprotects Troc selectively in the presence of methyl esters (you would expect that the methyl ester is quite labile to hydrolysis with hydroxide).

Tired of serious chemistry?

Take a break with “Periodic Tales – The Freshman Mole”, a satirical novel that’s the opposite of educational.

Dedicated to every chemistry and STEM student who asked: “Why did no one warn me?”

Troc protecting group in total synthesis

The very first introduction of the Troc protecting group was already… very advanced! Woodward and co-workers used the starting material below in the synthesis of cephalosporin C, an antibiotic natural product. [2]

What is the product after treating this molecule with Zn in aqueous AcOH?

This is a cool example where just one of the three groups decarboxylates. The others are not true Troc groups but were instead masking the free acid. If we do not have a free carbamate or carbonate after reductive elimination, we do not see a decarboxylation.

Thanks for checking out this article – feel free to read about other protecting groups or check out my educational videos!

Below you can find typical Troc protection and deprotection conditions.

Troc Protection conditions [3]

To a solution of the alcohol (0.80 g, 1.48 mmol) in methylene chloride (30 ml) at 0 °C was added pyridine (0.96 ml, 11.84 mmol, 8 equiv) followed by 2,2,2-trichloroethyl chloroformate (0.8 ml, 5.92 mmol, 4 equiv), and the reaction mixture was stirred at 0 °C for 1 h. Saturated aqueous sodium bicarbonate (50 ml) was added and the organic layer was separated. The aqueous layer was extracted with methylene chloride (3 x 50 ml), and the combined organic layers were dried over anhydrous sodium sulfate and concentrated in vacuo. Purification by flash column chromatography (2% EtOAc/hexanes) afforded protected product (0.98 g, 93%) as a colorless oil.

Troc deprotection conditions [4]

To a solution of protected Troc-amine (40 mg, 57 µmol) in 4 mL of MeOH was added activated zinc (400 mg). The mixture was stirred at 25 °C for 5 min, and glacial HOAc (4 mL) was added. The mixture was heated at 60 °C for 30 min, cooled and concentrated under reduced pressure. The residue was treated with 5 mL of 5% aqueous NaOH, and the solution was extracted with EtOAc (5 × 5 mL). The combined extracts were washed with brine, dried over anhydrous K2CO3, and concentrated under reduced pressure. Flash chromatography on silica gel (100:1 CH2Cl2/MeOH) gave 25 mg (86%) of the free amine as a viscous oil.

TROC Protecting Group References

- P. G. M. Wuts, T. W. Greene: Greene’s Protective in Organic Synthesis (Wiley)

- [1] Highly Chemoselective Deprotection of the 2,2,2 Trichloroethoxycarbonyl (Troc) Protecting Group | Barry M. Trost, Christopher A. Kalnmals, Jacob S. Tracy, and Wen-Ju Bai | Org. Lett. 2018, 20, 8043−8046

- [2] The Total Synthesis of Cephalosporin C. | Woodward, R. B.; Heusler, K.; Gosteli, J.; Naegeli, P.; Oppolzer, W.; Ramage, R.; Ranganathan, S.; Vorbruggen, H. | J. Am. Chem. Soc. 1966, 88, 852− 853

- [3] Patent WO2007/15929, 2007, A2

- [4] Total Synthesis of (±)-Symbioimine | Yefen Zou, Qinglin Che, Barry B. Snider | Org. Lett. 2006, 8, 24, 5605–5608

Leave a Reply

You must be logged in to post a comment.